Project Showcase

Mechanical Design of a Orion SAJ Proof Load Fixture

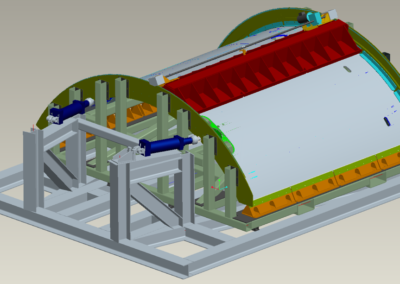

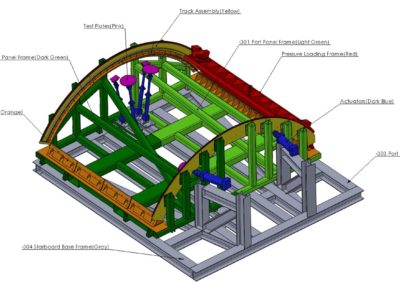

EMF routinely provides full mechanical design and engineering support. The test fixture shown below is used to perform proof of load testing of customer flight articles as part of the Orion Space Program. The system is designed to accommodate multiple test loads and is controlled with a pendant controller for translation. The test fixture was designed using CAD 3D modeling software. A finite element analysis (FEA) was performed to verify performance of the assembly under load. Using this software we are able to note any stress concentrations and degree of displacement prior to fabrication.

After the accuracy of the design was verified, the machined components were manufactured in our 5-axis CNC machining centers. The steel and aluminum substrates were treated with a chemical conversion coating in the case of steel, or anodized in the case of aluminum, before being painted with a three-coat system. The finished system measures 22′ in length, 22′ in width, 9′ in height, and weighs 20,000 lbs. This project demonstrates our ability to design, engineer, and fabricate complex mechanical systems for the aerospace industry.

For additional details regarding this custom mechanical design project, or to explore your next project, please contact us directly.

Project Highlights

Product Name

Orion SAJ Proof Load Fixture

Project Description

Mechanical design & test fixture mechanism to perform proof load testing of customer flight articles

Capabilities/Processes Applied Primary:

Mechanical Design

Analysis

Drafting

Equipment Used:

5- Axis Machining

Overall Fixture Dimensions:

Length: ~22′

Width: ~22′

Height: ~9′

Weight: ~20,000 lbs.

Material Used:

Steel, Aluminum

Material Finish

3 Coat Paint System, Alodine, Anodize

Industry for Use

Aerospace

Standards Met

AWS D1.1, AWS D1.2, Customer provided specifications for capacity and human safety